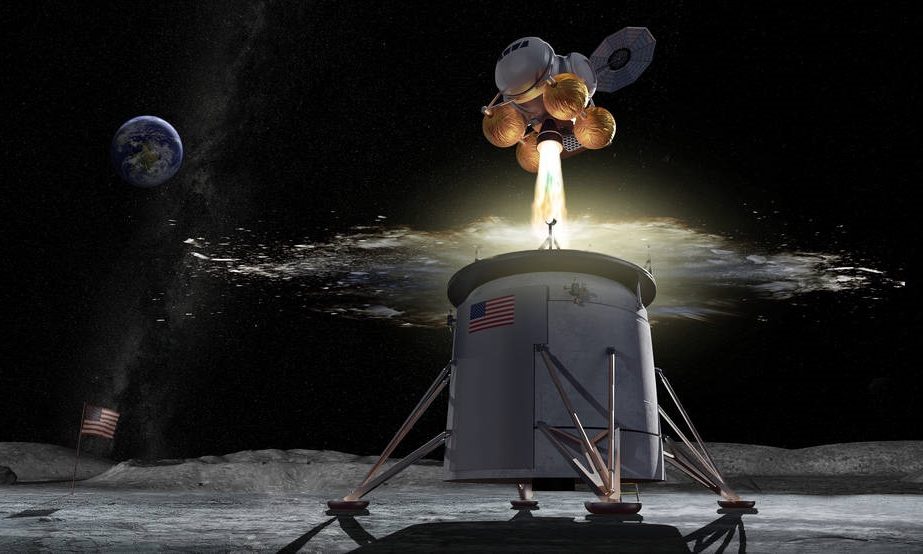

NASA’s Marshall Space Flight Center in Huntsville is expanding its partnership with the University of Alabama to collaborate on advanced and in-space manufacturing. In-space manufacturing is a priority in the space agency’s efforts to take American astronauts back to the Moon and beyond.

Marshall Director Jody Singer and UA President Stuart Bell signed a memorandum of understanding Wednesday, November 6 in the university’s Rose Administration Building shortly before the Space Days at UA official kickoff. The agreement aims to enhance inventive research assisting space exploration and strengthen the education of tomorrow’s aerospace workforce.

“Additive manufacturing is a rapidly evolving, disruptive technology,” Singer said. “As NASA continues to invest in in-space additive technology innovations, we welcome collaborations with industry and academia to develop these technologies. I applaud the University of Alabama for pursuing the development of advanced technologies that will help NASA achieve our mission.”

In-space manufacturing includes making the materials needed for the mission using components brought from Earth or gathered from the moon or Mars. It could include additive manufacturing processes like 3-D printing with plastics, electronics or metals along with the capabilities to design and characterize the materials.

“Our partnership with NASA is an important priority in our efforts to provide opportunities for our students and researchers to offer solutions to leading-edge challenges,” Bell said. “Working to further in-space manufacturing will establish the University’s expertise in the area while training a skilled workforce our state can rely on to remain competitive in the global economy.”

Economic developer Nicole Jones said, “In-space manufacturing can be used in conjunction with additive manufacturing, also known as 3-D printing, which refers to the process of building parts through the combination of material, layer-by-layer, from a CAD file. “

The University has agreed to enhance its core curriculum in areas of advanced and in-space manufacturing and foster new collaborations to further this emerging technology. The areas of emphasis include modeling, analysis and simulation, data analytics, robotics, rendezvous and capture, navigation, advanced materials, on-site resource utilization, additive manufacturing, digital design, and manufacturing and construction.

Marshall has entered into agreements with several colleges and universities. Marshall has made several agreements with the University of Alabama under the Space Act. NASA has agreed to share its resources, personnel and expertise, facilities and equipment, and technology with UA to advance aerospace research or achieve mission goals.

“We are in another historic space race, and the partnership between NASA Marshall and the University of Alabama will allow for research and development of these new technologies,” Dr. Nicole Jones said.

NASA and its aerospace contractors are major employers in the state of Alabama.